Tin plating

Tin plating is a process that is proven in the food and electrical industries, among others. An applying of the tin layer can be made in several different ways, so it is worth using the services of the plant, which has extensive experience and adequate technical facilities. We invite you to cooperation.

Galvanic tinning in a professional plant

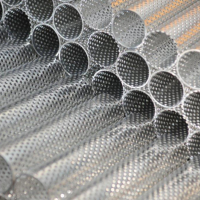

Tin coatings work well as a power conductor, for example in the electrical industry. The further advantages of this layer are: good soldering possibilities and the possibility of contact with food. Due to the fact we use sulphate baths and shiny accessories for tinning, the visual effect meets all relevant standards. It is not insignificant we choose top-class technology from companies such as ATOTECH, SurTec or SCHLOETER.

How we carry out the tin plating process

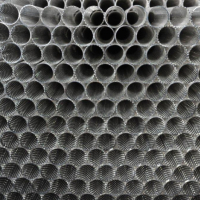

The steel as well as aluminum and brass parts can be treated by the galvanic tinning process, which gives to manufacturers a lot of possibilities. In the case of brass details it is necessary to apply a coating of nickel or copper beforehand, and in the case of aluminum - a layer of zinc.

Tin plating step by step

In order for tin plating to proceed as planned, it is necessary to act methodically. In our plant, the process takes place according to the following scheme:

- chemical degreasing with ultrasounds;

- digestion;

- electrochemical degreasing;

- activations;

- tin plating;

- final processing;

- drying.

Due to meeting the proven technology, we give you a guarantee of quality. We always adapt to the customers' requirements and we together search for the best possible solutions. The test batch aims to check everything before proceeding to the final work on the tin plating. Effects ? Adhesive, adequately shiny and soldering coatings, whose thickness is accurately measured with the Fisher’s measuring apparatus.

Contact by phone - 74 637 91 71.

|

|

|

|

|

|

|