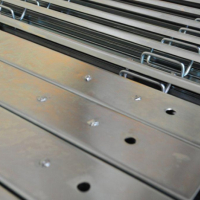

Galvanic zinc plating

The galvanic zinc plating is a process whose task is to increase the rust resistance of steel materials. For this purpose, an electrolysis (i.e. electrical voltage) is being used. If you want to effectively protect some steel elements against corrosion, galvanizing is a very good choice. In our factory, we make them in a professional and safe way.

Resistance to rust by application a galvanic zinc plating

The galvanizing process starts with the degreasing of materials, for which we use alkaline liquids having a high pH. The next stage is the digestion, or soaking of materials in low pH acids, which allows for the elimination of mill scale and rust. After pickling, it's time for the most important phase, which is galvanizing. In order to increase the resistance of the material to rust, we apply many-coloured passivations: blue and a high-passivation, as well. The polymer varnishes are an additional method used by us to obtain even better protection against corrosion.

The galvanic zinc plating is useful in the following industries:

- automotive industry;

- building;

- electronic industry;

- aircraft industry;

- household appliances and electronics;

- gardening.

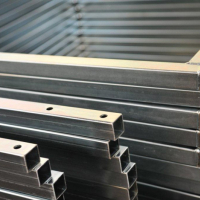

Versatility and safety

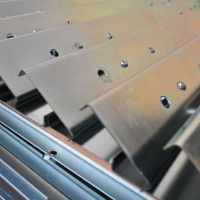

The galvanizing process is a service with a very wide and universal application, which is used in many industries and sectors. It is used in the production of fences, flat bars, angles, hinges, covers, subassemblies, antennas, fence nets, chains, screws, nails and car parts. We do not even realize how many objects and elements surrounding us every day have been galvanized.

We offer two galvanizing methods:

- drums, used for small elements up to 100-150 mm, where light scratches are acceptable;

- hanger, suitable for large items, on which even small scratches are unacceptable.

After galvanizing, we use different types of passivations:

- thin-layer with an aesthetic blue colour, which, however, is characterized by a low resistance to rust;

- thick, transparent, with good anti-corrosion properties;

- black, with low rust and scratch resistance;

In order to improve the anti-corrosion properties, we use the polymer varnishes that we use during or after the passivation process.

We cordially invite you to cooperation and taking advantage of the excellent properties that professional galvanic zinc plating process offers.

Contact by phone - 74 637 91 71.

Basing on our 30-year experience we realize galvanic zinc plating process, as well as the other processes, with a focus on:

- customer satisfaction

- short period of implementation (even on the spot)

- highest quality

- nice, helpful and professional service

- willingness to help everyone

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|